Die Produkte hinter den Türchen des Adventskalenders sind mit Sorgfalt ausgesucht und in eine gewisse Reihenfolge gebracht worden. Nachdem die ersten elektronischen Experimente am besten auf einem Breadboard, dem Steckbrett, durchgeführt werden (siehe Blog vom 01.12.), kommt man dennoch in der Welt der Maker nicht darum herum, gelegentlich zum Lötkolben zu greifen.

Bevor man jedoch als Anfänger die Pin-Leisten an einen teuren Micro Controller oder ein Display anlötet, sollte man seine ersten Erfahrungen an einem einfacheren und preiswerteren Objekt machen. Deshalb habe ich auch zunächst geübt, bevor ich selbst nach längerer Pause die Pin-Leisten an dem schwierigen WiFi LoRa32-Board angelötet habe: an dem DIY Weihnachtsbaum-Kit mit vielen Widerständen und LEDs sowie einigen Kondensatoren und Transistoren. An dieser Stelle möchte ich als fortgeschrittener Amateur meine Erfahrungen weitergeben.

Meine Ausrüstung

|

Am Lötkolben sollte man nicht sparen, aber für unser Vorhaben „Beinchen anlöten“ muss es keine teure, regelbare Lötstation sein. Beim Lötzinn bevorzuge ich den dünnen Draht mit 0,56 mm Durchmesser. Lötzinn ist übrigens meist eine Zinn-Blei-Legierung, dessen Schmelzpunkt zwischen 180 °C und 260 °C und damit niedriger als der der Hauptbestandteile liegt. Als Flussmittel wird Kolophonium beigefügt. Dämpfe bitte nicht einatmen. Im Profibereich müssen Absaugvorrichtungen verwendet werden. Ich puste die Dämpfe während des Lötvorgangs weg.

Wenn einmal etwas schief gegangen ist oder ein defektes Bauteil entfernt werden muss, bedarf es einer Entlötpumpe. Aber nicht zu viel davon erwarten: eine komplette Pin-Leiste kann man damit eher nicht auslöten. Am besten klappt es, wenn man das Bauteil nach dem Erhitzen des Lots herausziehen kann.

Das blaue Teil links im Bild ist eine Biegehilfe für Widerstände usw. Und die Flachzange benötigen wir zum Abschneiden des überflüssigen Drahtes an den Bauteilen nach dem Löten. An einem nassen Schwamm kann man gelegentlich die Lötspitze reinigen (der billige Haushaltsschwamm ist nicht wirklich gut geeignet). Und der linke Schwamm kommt ins Spiel, wenn wir die Bauteile auf der Platine fixieren wollen, bevor wir diese zum Löten umdrehen.

Unser Versuchsobjekt

|

Die beiden Platinen des Weihnachtsbaums liegen hier noch übereinander. Sie sind unterschiedlich, weil sie am Ende zusammengesteckt werden.

|

Sehr hilfreich ist, dass die beiden Platinen mit Symbolen und Bezeichnungen bedruckt ist. Dort montieren wir die Bauteile, um sie später auf der Rückseite zu verlöten.

Wir beginnen aus zwei Gründen mit den Widerständen; sie sind einerseits flach und stehen den anderen Bauteilen bzw. dem Lötkolben später nicht im Wege, und andererseits sind es die billigsten Bauteile. Auf jede Platine kommen je drei Widerstände a‘ 1 kΩ (kΩ=Kilo Ohm) und 10 kΩ, nur auf eine Platine kommt zusätzlich ein 2,2 kΩ-Widerstand.

|

Bezeichnung |

Wert |

Ring 1 |

Ring 2 |

Ring 3 |

Ring 4 |

|

R1, R3, R5 |

10 kΩ |

Braun |

Schwarz |

Orange |

Gold |

|

R2, R4, R6 |

1 kΩ |

Braun |

Schwarz |

Rot |

Gold |

|

R7 |

2,2 kΩ |

Rot |

Rot |

Rot |

Gold |

|

Zum vorläufigen Fixieren gibt es zwei Tricks: erstens die Drähte nach dem Durchstecken nach außen biegen, und zweitens die Bauteile vor dem Umdrehen mit dem Küchenschwamm fixieren.

|

Nun wird es heiß! Bitte den Lötkolben am Griff anfassen und mit der Spitze den Draht des Bauteils erhitzen. Dann den Lötdraht von der wenige Zentimeter abgewickelten Rolle Lötzinn gegen den Draht halten, bis genügend Lot geflossen ist. Erst das Lötzinn wegziehen, dann den Lötkolben.

Ergebnis begutachten. Ein kleiner Kegel rund um den Draht? Loch auf der Platine verschlossen? Alles gut. Und wenn nicht – wir üben ja noch und haben noch viel vor uns. Damit die langen Drähte nicht weiter stören, werden sie nach dem Anlöten abgeknipst.

Fangfrage: Haben Sie die Widerstände richtig herum eingesteckt? Kommt nicht darauf an!

Aber aufgepasst. Bei den nächsten Bauteilen ist die Polarität wichtig. Wir wollen auf jeder Platine drei Elektrolyt-Kondensatoren einlöten. Die Elkos habe zwar eine deutlich höhere Kapazität als gleich große, „normale“ Kondensatoren, aber hier muss unbedingt auf Plus und Minus geachtet werden. Auf der Platine sehen wir an den jeweiligen Stellen ein schraffiertes Feld und ein freies Feld mit einem kleinen Pluszeichen.

Am Bauteil selbst sehen wir zwei unterschiedlich lange Beinchen (werden wir auch bei den LEDs sehen) und am Gehäuse auf der Seite des kürzeren Beinchens einen weißen Balken, das überdimensionale Minuszeichen. Denken Sie beim Biegen daran, dass der Kondensator am Ende flach liegen soll.

|

Je drei Transistoren mit einer runden und einer flachen Seite sind so auf der Platine aufgezeichnet, dass man beim Einstecken nicht viel falsch machen kann. Aber bitte keine Gewalt anwenden. Das Gehäuse bleibt in geringem Abstand von der Platine (siehe hinterer Transistor) aufgrund des Abstands der Löcher.

|

Nun geht es an die 18 LEDs je Platine. Wie vorhin schon angemerkt, sind auch LEDs Bauteile mit Polarität. Das längere Beinchen ist wieder der Pluspol, Anode genannt. Und das kürzere Beinchen ist der Minuspol, Kathode genannt. Auf der Seite der Kathode ist das Gehäuse abgeflacht, aber bei den kleinen LEDs kann man das kaum sehen oder fühlen.

Eingesteckt werden die LEDs so, dass das längere Beinchen durch das rechteckige Lötpad und das kürzere Beinchen durch das runde Lötpad gesteckt wird. Alle Kathoden zeigen zur Baumspitze.

|

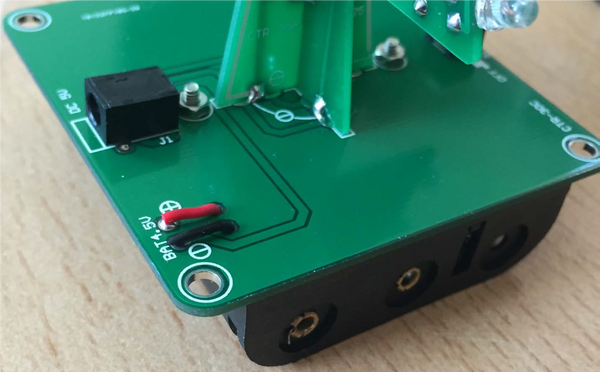

Beim Durchstecken habe ich gemerkt, dass die LEDs aufgrund einer kleinen Verdickung an den Beinchen mit etwas Druck durch die Löcher geschoben werden können. In dieser Position kann man die LEDs dann perfekt nach außen biegen. Ein letzter Kontrollblick – die kürzeren Beinchen zeigen Richtung Spitze – und los geht’s. Und wenn wir gerade so gut dabei sind, werden der Schalter und die kleine Strombuchse auf der Grundplatte festgelötet.

Am Schluss wird es noch einmal etwas fummeliger, wenn man nicht eine helfende Hand hat. Die beiden Platinen sollen ineinandergeschoben und dann mit der Grundplatte verlötet werden, also in der rechten Hand den Lötkolben, in der linken das Lötzinn, aber wer hält die Platinen stramm auf der Grundplatte?

Ich habe die beiden Teile wieder auseinandergezogen und eines mit einem Gummiband fixiert. Bitte auch hier auf die Polarität achten. Über die Grundplatte erfolgt die Spannungsversorgung der Weihnachtsbaumbeleuchtung.

|

Dann die zweite Platine mit richtiger Polarität aufstecken und mit der Grundplatte verlöten. Fertig? Noch nicht ganz. Zum Schluss wird die LED für die Baumspitze angelötet. Wer sich für das mitgelieferte USB-Kabel als Spannungsversorgung entscheidet, ist nun fertig. Ansonsten wird der mitgelieferte Batteriehalter für drei Mignon-Batterien unter der Bodenplatte mit den 2 Schrauben und Muttern befestigt und die 2 Drähte, entsprechend gekürzt, angelötet.

|

Ich wünsche viel Spaß beim Nachbauen und mit der etwas anderen Weihnachts-Dekoration.

7 comments

Alfred Ruethlein

Etwas verwirrend, vor allem für Basteleinsteuger, sind die unterschiedlichen Widerstandswerte die in veschiedenen Dokumentan genannt werden und bei Lieferung des Bausatzes;

R1,3,5: 10k, 4,7k, Lieferung 10k

R2,4,6: 1k, 100, Lieferung 150

R7: 2,2k, 100, Lieferung 470

Ist vermutlich nicht ohne große Auswirkung aber trotzdem verwirrend!

Bernd Albrecht

@ maurilio fiorito: Unser italienischer Freund hatte uns auf einen Übersetzungsfehler im IT eBook aufmerksam gemacht. Danke dafür. Wir haben den Fehler korrigiert.

@ Heinz Köppe: Die von Ihnen gewünschten Angaben finden Sie im Datenblatt auf der Produktseite. https://cdn.shopify.com/s/files/1/1509/1638/files/DIY_Weihnachtsbaum_Kit_Datenblatt.pdf?6283934366688661570

Heinz Köppe

Wenn ich etwas baue, sollte es nicht nur die Geschicklichkeit fördern, sondern auch das technische Wissen erhöhen. Dazu gehören nähere Angaben über die Bauteile. Was sind das für Transistoren , wie belastbar sind die Widerstände usw.. Wie können LED mit nur zwei Anschlüssen drei Farben anzeigen und eine Erläuterung der Funktion der Schaltung wäre auch interessant.

maurilio fiorito

forse ho sbagliato qualcosa, ma tre alberi su tre hanno accesa solo la punta. Il book però scambia la saldatura dell’anodo con il catodo, quindi ho saldato tutti i led al contrario?

Franz Twelsiek

@Straube SO ENDSTEHEN WAKELKONTAKTE; NACH 48 JAHRE SISTEMELEKTRONIK WEISS ICH WOHL WO VON WIR ELEKTRONIKER REDEN. OFFENER KUPFERDRAHT DARUM ZINN & DANN LUFTFEUCHTIGKEIT NACH DREI JAHREN KÖNNEN SIE DAS BAUTEIL RAUSZIEHEN !

Daniel Straube

super erklärt und schön dpkumentiert.. ist mal gelungen. @twelsiek : das mit dem abschneiden vor dem löten finde ich schwachsinn und hab ich noch nirgends gesehen

Franz Twelsiek

Ich habe gelernt, den Draht vor dem Verlöten abzukneifen als Schutz für Korrosion zwischen Kuper und Zinn.